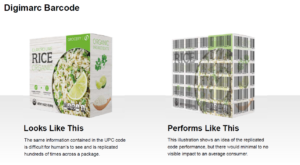

Digimarc has several considerable advantages over the classic EAN code. We have already mentioned one – it is nearly invisible for the eye. How is it possible? “The Digimarc technology is based on using corrections of points and their differences in contrast in a picture or in selected elements of a design. To put it in a simpler way: Digimarc is a code built of repetitive 2D patterns which comprise spots minimally contrasting with each other “embedded” in a packaging graphic design. The system of pixels designed in this way enables barcode scanners, smartphones or cameras to detect encoded information,” explains Marcin Szumigaj, Business Implementation Manager in Akomex Group. Since the end of 2019, the solution has been tested by international food chains and if pilot programs go well, the Digimarc technology may quickly become part of the mainstream.

Akomex Group with recommendation

Akomex Group is on the official list of recommended Digimarc partners, and packaging with the digital watermark has been manufactured by it already since 2019.

“Akomex Group has already completed several hundred packaging projects with the Digimarc system, inter alia for manufacturers of sweets, dairy sector or fish sector. Cooperation with leading European brands says the most about our readiness for work with this technology,” explains Marcin Szumigaj.

Transparency builds up the image

From amongst the unique benefits of Digimarc those related to sustainable development come first. It enables instant access to information about a product, which may be updated in real time (e.g. at a website). Thanks to this, consumers gain complete information related to origin of raw materials used for production, carbon footprint or place and way of manufacturing, let alone such data as nutritional values. Customers care about transparency more and more. In research from 2018, as many as 75% consumers confirmed that they would change a brand into a one which provides complete information about its product. And 84% of them declared that at least once in a while they check origin of their food.

From amongst the unique benefits of Digimarc those related to sustainable development come first. It enables instant access to information about a product, which may be updated in real time (e.g. at a website). Thanks to this, consumers gain complete information related to origin of raw materials used for production, carbon footprint or place and way of manufacturing, let alone such data as nutritional values. Customers care about transparency more and more. In research from 2018, as many as 75% consumers confirmed that they would change a brand into a one which provides complete information about its product. And 84% of them declared that at least once in a while they check origin of their food.

It is particularly significant to companies which have sustainable development in their DNA. And a transparent and responsible attitude builds up loyalty towards a given brand. The food sector is a good example, where the place or way of acquiring raw materials are of crucial importance in terms of quality of a product and care of the environment. Thanks to the direct link between a customer, product and brand the word “communication” gains another dimension, and its borders are built up by imagination only. “In this way, brands can create their image and enhance consumers’ confidence,” explains Marcin Szumigaj. “It is also a way of building prestige. Consumer and market trends expressly show that transparency and responsibility are precious values on the market,” adds Szumigaj.

An instance of a world leading manufacturer of Atlantic salmon is particularly interesting. Thanks to Digimarc, the company enables its customers to track the whole life cycle of the fish bought by them. Consumers can verify where and when it was grown, what it was fed with, and even how much it weighed at the time of catching.

Recycling of the future

However, it is not the end of Digimarc benefits in the context of sustainable development. Its recycling potential may be the real revolution. Within the framework of the Holy Grail 2.0 project, conducted by the AIM (European Brand Association), the technology of digital watermark is tested in waste sorting plants. Cameras read information from products, encoded in Digimarc, identify a given raw material, and sorting devices automatically assign them to a relevant category. Thanks to it, segregation of waste is quicker and more effective, which has a favourable influence on the quantity and quality of plastic to be recycled. Introduction of such a solution on a wide scale would be a significant step towards the circular economy because now a relatively small amount of plastic is actually recycled.

Benefits for manufacturers…

Benefits for consumers and producers do not end with sustainable development. Digimarc also has a lot more “down-to-earth” uses. First of all, it does not occupy place on packaging. It is particularly essential in the case of small labels where the classic EAN code occupies a large surface and has an adverse influence on how the product is presented on a shelf. Its other functions include, for example, control of quality, facilitating logistics processes, serialization of packaging or protection against placing imitations on the market.

Marketing is another use. As we have already mentioned, information encoded in Digimarc may contain links. It provides consumers with quick access to the brand content: social media, loyalty programs or current promotions. A reference to a particular content in the network may help to present e.g. instructions, recipes, dietetic guidelines, non-standard methods of supporting treatment or contents which promote a healthy lifestyle. Getting directly to a customer in this way allows building new models of purchasing paths.

… and consumers

Because of the fast pace of life nowadays, consumers have less and less time. No wonder that brands outdo one another in making their lives easier. For consumers, Digimarc mainly means more effective scanning of products at cash desks. And this, in turn, is reflected in shorter queues and faster shopping, which is perfectly embedded in the convenience trend. Following this lead – in the future it is not hard to imagine that by scanning codes from products, the devices remind e.g. about shortages in food stocks, expiry dates, necessity to carry out a control test or necessity to take up other actions aimed at ensuring our safety.

Production of packaging with Digimarc naturally forms part of Akomex Group strategy . This company has been tracking trends on the market for a long time, as well as taking active part in creating solutions which lead to sustainable development and circular economy.